FLEXCO NEWS

New Flexco® XP™ Staple Fastening System Produces High-Quality Splices with Manual and Powered Installation

Flexco recently announced the addition of the Flexco® XP™ Staple Fastening System to its robust line of fastening solutions. The XP Staple Fastening System combines an enhanced applicator tool with the longest-wearing staple fastener and hinge pin on the market to produce a superior belt splice in the toughest mining applications.

Flexco recently announced the addition of the Flexco® XP™ Staple Fastening System to its robust line of fastening solutions. The XP Staple Fastening System combines an enhanced applicator tool with the longest-wearing staple fastener and hinge pin on the market to produce a superior belt splice in the toughest mining applications.

Designed for use with solid woven PVG/PVC belting and ply belts, the XP comes in several sizes, ranging from belt tension ratings of 800 – 2000 PIW (belt strengths up to 1400 – 3500 kN/m) and belt thicknesses of 1/4” (6 mm) to 25/32” (20 mm). All sizes are available with steel and stainless fastener plates. A larger, more durable loop area eases pin installation and allows larger pins to be inserted.

“The use of cold-rolled steel provides uniform mechanical properties and increased tensile strength of up to 50%,” Aaron Rosso, senior product manager at Flexco, said. “Along with increased strength, the finished splice also has a smooth, low-profile, which discourages damage to belt cleaners and other conveyor components.”

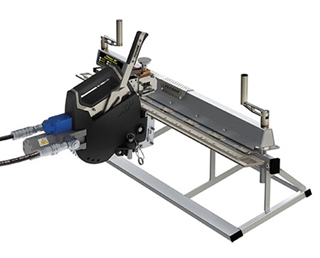

Application of staple fasteners is easy, with manual, pneumatic, and hydraulic tools that are easy to set up and maintain. The frame and applicators are built for durability, but easy to transport. The integrated guide plate on the frame helps load heavy belts, making splice preparation faster and easier. A built in belt-thickness gauge confirms proper fastener size and setting selection for an optimal splice with both tools.

The XP™ Manual Applicator Tool features an oversized handle design that gives users the ability to choose multiple hand positions based on worksite conditions. The quick adjustability of the handle allows workers to optimize the handle length for reduced effort and increased mobility.

The single-lever XP Pneumatic and Hydraulic Applicator Tools compress the plate, then drive and fold the staples in one smooth motion, producing a consistent, quality staple set and finished splice profile every time. During the process, only one fastener is set at a time, decreasing the chance of misdrives and tool jams. Should the occasional misdrive occur, the tool allows the operator to skip over it, continue the splice, and return to drive the staple again.

All the applicator tools have a sealed housing that discourages material build up on internal components, making it easy to maintain. They mount quickly to the frame and are readily positioned for splicing.

For more information on the XP Staple Fastening System or any other Flexco splicing solutions, click here.

Published Date

June 16, 2021Product Group

- Mechanical Belt Fastening Systems